I figure not many people look around the DIY section so i would put it here

So this is sort of a DIY, I didn't take pictures as I built it because I figured there are plenty of how to’s all over the web but wanted to share my short experience so far. But here is one of it installed.

I used a 4" PVC tube about 15" long. I got a 100’ coil of irrigation line ¼” O.D. I cut small pieces off to run in and out lines then cut the rest in half. The I wrapped one of the approximately 50’ lines around the inside of the pvc pipe, then wrapped a the second 50' coil on the inside of that. I used super glue to get the hose to stay in place for a coil or two, after that it stayed on its own. With my big hands the second one was a bit difficult. Then I glued a cap onto the bottom

For bio media on the inside; I have read that not a lot is needed and I didn't want to buy any to keep cost down. So I cut off 4 pieces at 1" off of the 4" pvc. I then cut those in half and sanded them all over to rough them up well. Then I put them inside. This plus the surface area of the coil should be plenty of surface area. Some people I’ve read put 6 or 8 bio balls in there.

The top pieces of the two coiled hoses I connected with a tee that had another piece of tubing running through the top cap. I drilled a hole that the hose barley fit through then put silicone around the hose on the inside. Also on the cap I threaded a brass barb into to hook another hose to go up to the tank, also using silicone on the inside. Then I glued the cap on. I had to add some glue to the joints to make it water tight; found a leak while testing it.

I have PVC for return lines on my canister filter. I added a ball valve going to the tank to throttle more water to the denitrator if necessary; also I have a ball valve going to the denitrator so I can shut off flow when doing maintenance on the regular filter so air does not get into the denitrator. And there is a small John Guest ball valve going into the denitrator. I could just close this when doing maintence but then I would lose my flow setting and it’s not an easy thing to adjust.

So water comes out of my canister filter, then it goes back to the tank but some is diverted to the coil denitrator. Once it enters it splits into two 50' hoses. It exists the hose at the bottom and flows past the pvc bits and exists the top of the unit back to the tank, dripping into the tank to help re-oxygenate and degas.

My tank has been up and running for a few years, it has been taken down and moved twice but the beneficial bacteria have not be greatly disturbed. I had to do a 100% water change so I could move the tank (75 gal.) I have a messy turtle so hopefully this cuts back on water changes.

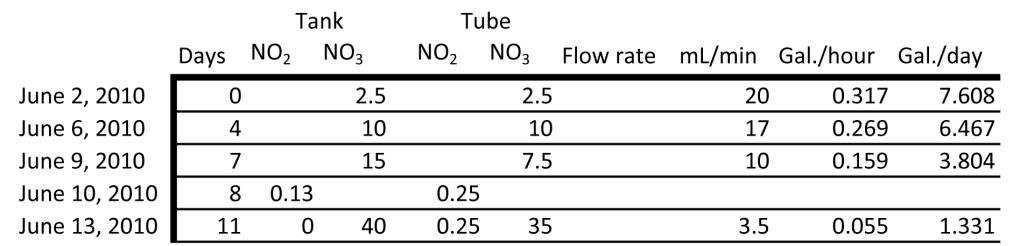

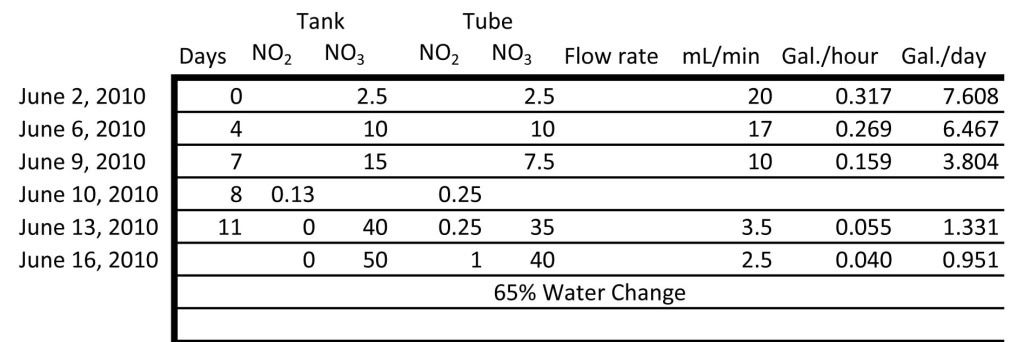

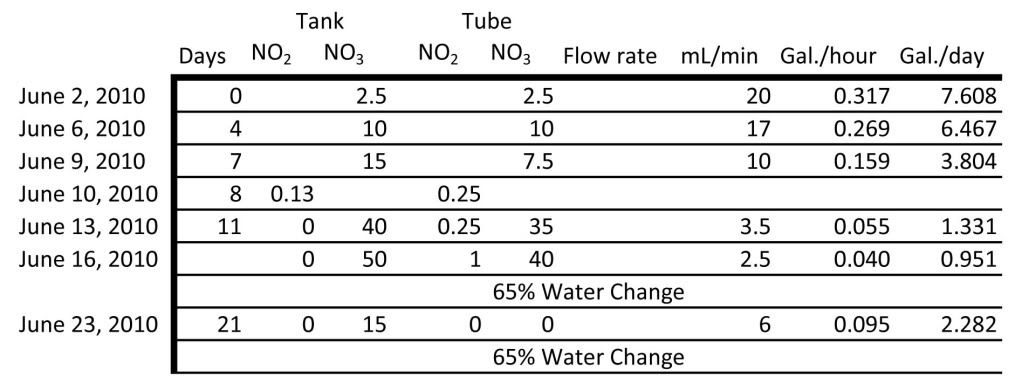

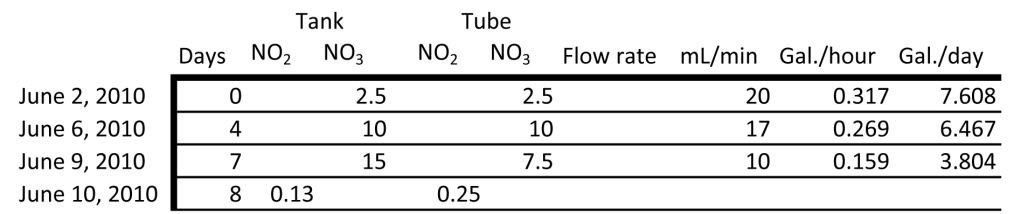

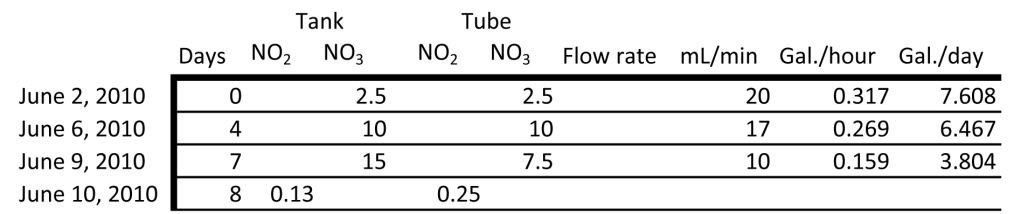

Here is a chart I have going in excel of my results, I didn’t have a nitrite test kit until today and didn’t feel like testing nitrates again after just one day. As you can see the coil has started to work quickly which I think has to do with my tank being well established. I did find out that I have nitrites coming out of the unit but they are at upper threshold of safety for fish, but the tank as a whole is reading lower, plus turtles can take more than fish since they don’t breath through the water. I will monitor these levels and if they don’t come down soon I will slow the flow more so that the nitrites can be completely converted to nitrogen. As I explain later the flow can be turned back up once the unit has been cycled more.

So for those of you who do not know I will explain how this devise works to the best of my knowledge:

Water flows through the tubes (slowly as you may have noticed). As with any surface in an established tank there is beneficial bacteria growing on it, so this means hoses also gets beneficial bacteria growing on the inside. Ammonia will be converted into nitrites and on to nitrates as with any biological filter. Given the slow flow rate and high surface to volume ratio the water will lose oxygen as the bacteria use it up. The water then enters the open area of the tube with nitrates and low oxygen. There is a bacterium that will break down nitrates in this anaerobic environment. They convert the nitrates back to nitrites and then the nitrites to nitrogen gas. Note: each conversation happens from a different type of bacteria, but all part of the complete nitrogen cycle. The feed water does not need to be fully filter as I have it but it should be mechanically filter to stop the unit from clogging.

Commercial denitrators are feed a carbon source and it makes them much more efficient, I will take no maintenance over peak efficiency in this case. As the denitrator is cycling it will produce nitrites which should be taken care of by your regular filter. By slowing the flow you will reduce nitrites during the cycling processes. Once you are showing no nitrites or nitrates in the out flow you can slowly turn the flow rate up. Turn it up very slowly and wait a few days or a week and make sure you still are not getting nitrates or nitrites. If the flow is too slow you can get hydrogen sulfate gas produced which smells like rotten eggs. The idea is to have the flow as fast as possible while not having nitrates or nitrites coming out.

By having two separate lines I should be able to have a decent flow rate. This will not eliminate water changes because there are other things that build up in a tank then nitrates, such as phosphates. But these other things are less harmful and do not accumulate as fast meaning water changes can be done less often. Which means less work, saving water, and less stress to the inhabitants.

Any questions or comments please bring them on, I’m not an expert but I have done a bit of research on this so I feel fairly confident for just starting one up.

This devise has the potential to be harmful given that if not properly tuned and watched it can give of nitrites, and hydrogen sulfide. Also the water coming out will have almost no oxygen in it. However if tuned right and allowed to drip in the tank, plus the low volume going into the tank there should not be any issues. The best place to drip the out flow is in to water that is well aerated such as a sump but dripping through the air will also work.

Feel free to ask questions or give comments, I’m not an expert on this as I’m just starting off but I have done a bit of research on this and feel somewhat confident about what I’m doing.

So this is sort of a DIY, I didn't take pictures as I built it because I figured there are plenty of how to’s all over the web but wanted to share my short experience so far. But here is one of it installed.

I used a 4" PVC tube about 15" long. I got a 100’ coil of irrigation line ¼” O.D. I cut small pieces off to run in and out lines then cut the rest in half. The I wrapped one of the approximately 50’ lines around the inside of the pvc pipe, then wrapped a the second 50' coil on the inside of that. I used super glue to get the hose to stay in place for a coil or two, after that it stayed on its own. With my big hands the second one was a bit difficult. Then I glued a cap onto the bottom

For bio media on the inside; I have read that not a lot is needed and I didn't want to buy any to keep cost down. So I cut off 4 pieces at 1" off of the 4" pvc. I then cut those in half and sanded them all over to rough them up well. Then I put them inside. This plus the surface area of the coil should be plenty of surface area. Some people I’ve read put 6 or 8 bio balls in there.

The top pieces of the two coiled hoses I connected with a tee that had another piece of tubing running through the top cap. I drilled a hole that the hose barley fit through then put silicone around the hose on the inside. Also on the cap I threaded a brass barb into to hook another hose to go up to the tank, also using silicone on the inside. Then I glued the cap on. I had to add some glue to the joints to make it water tight; found a leak while testing it.

I have PVC for return lines on my canister filter. I added a ball valve going to the tank to throttle more water to the denitrator if necessary; also I have a ball valve going to the denitrator so I can shut off flow when doing maintenance on the regular filter so air does not get into the denitrator. And there is a small John Guest ball valve going into the denitrator. I could just close this when doing maintence but then I would lose my flow setting and it’s not an easy thing to adjust.

So water comes out of my canister filter, then it goes back to the tank but some is diverted to the coil denitrator. Once it enters it splits into two 50' hoses. It exists the hose at the bottom and flows past the pvc bits and exists the top of the unit back to the tank, dripping into the tank to help re-oxygenate and degas.

My tank has been up and running for a few years, it has been taken down and moved twice but the beneficial bacteria have not be greatly disturbed. I had to do a 100% water change so I could move the tank (75 gal.) I have a messy turtle so hopefully this cuts back on water changes.

Here is a chart I have going in excel of my results, I didn’t have a nitrite test kit until today and didn’t feel like testing nitrates again after just one day. As you can see the coil has started to work quickly which I think has to do with my tank being well established. I did find out that I have nitrites coming out of the unit but they are at upper threshold of safety for fish, but the tank as a whole is reading lower, plus turtles can take more than fish since they don’t breath through the water. I will monitor these levels and if they don’t come down soon I will slow the flow more so that the nitrites can be completely converted to nitrogen. As I explain later the flow can be turned back up once the unit has been cycled more.

So for those of you who do not know I will explain how this devise works to the best of my knowledge:

Water flows through the tubes (slowly as you may have noticed). As with any surface in an established tank there is beneficial bacteria growing on it, so this means hoses also gets beneficial bacteria growing on the inside. Ammonia will be converted into nitrites and on to nitrates as with any biological filter. Given the slow flow rate and high surface to volume ratio the water will lose oxygen as the bacteria use it up. The water then enters the open area of the tube with nitrates and low oxygen. There is a bacterium that will break down nitrates in this anaerobic environment. They convert the nitrates back to nitrites and then the nitrites to nitrogen gas. Note: each conversation happens from a different type of bacteria, but all part of the complete nitrogen cycle. The feed water does not need to be fully filter as I have it but it should be mechanically filter to stop the unit from clogging.

Commercial denitrators are feed a carbon source and it makes them much more efficient, I will take no maintenance over peak efficiency in this case. As the denitrator is cycling it will produce nitrites which should be taken care of by your regular filter. By slowing the flow you will reduce nitrites during the cycling processes. Once you are showing no nitrites or nitrates in the out flow you can slowly turn the flow rate up. Turn it up very slowly and wait a few days or a week and make sure you still are not getting nitrates or nitrites. If the flow is too slow you can get hydrogen sulfate gas produced which smells like rotten eggs. The idea is to have the flow as fast as possible while not having nitrates or nitrites coming out.

By having two separate lines I should be able to have a decent flow rate. This will not eliminate water changes because there are other things that build up in a tank then nitrates, such as phosphates. But these other things are less harmful and do not accumulate as fast meaning water changes can be done less often. Which means less work, saving water, and less stress to the inhabitants.

Any questions or comments please bring them on, I’m not an expert but I have done a bit of research on this so I feel fairly confident for just starting one up.

This devise has the potential to be harmful given that if not properly tuned and watched it can give of nitrites, and hydrogen sulfide. Also the water coming out will have almost no oxygen in it. However if tuned right and allowed to drip in the tank, plus the low volume going into the tank there should not be any issues. The best place to drip the out flow is in to water that is well aerated such as a sump but dripping through the air will also work.

Feel free to ask questions or give comments, I’m not an expert on this as I’m just starting off but I have done a bit of research on this and feel somewhat confident about what I’m doing.